- 1 月 22, 2026

- News

- 0 Comments

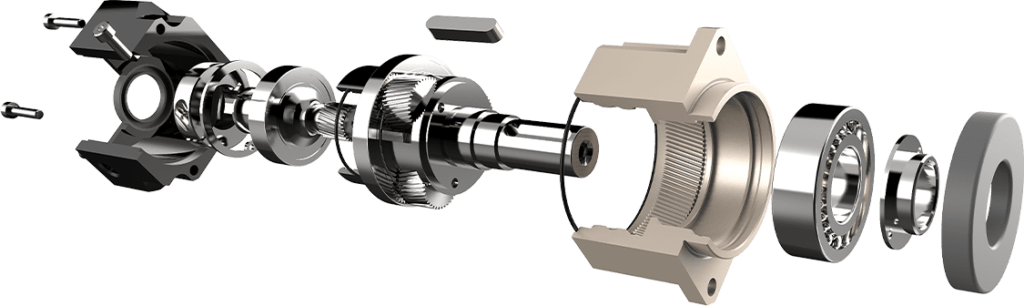

Backlash is one of the most critical yet often misunderstood parameters in gear reducer production. While often viewed as an undesirable mechanical characteristic, backlash plays an essential role in ensuring smooth operation, durability, and manufacturability. For a quality-driven gear reducer manufacturer like GEARKO, controlling backlash is not simply about minimizing clearance—it is about engineering the optimal balance for each application.

Understanding Backlash in Gear Reducers

Backlash refers to the intentional clearance between mating gear teeth, observable as a small amount of lost motion when the direction of rotation changes. This clearance is influenced by gear geometry, manufacturing tolerances, lubrication needs, thermal expansion, and assembly conditions.

In professionally engineered gear reducers, backlash is a carefully designed parameter rather than a defect.

Why Backlash Is Critical in Gear Reducer Production

1. Smooth Operation and Load Distribution

Proper backlash prevents gear tooth interference and binding under load. Without adequate clearance, slight misalignments, shaft deflection, or housing deformation can lead to excessive friction and localized stress.

At GEARKO, backlash values are engineered to ensure full tooth engagement and uniform load distribution, enhancing reducer efficiency and extending service life.

2. Managing Manufacturing Tolerances

Even with advanced CNC machining and gear grinding, microscopic variations in tooth profile and pitch are unavoidable. Backlash provides the necessary tolerance buffer that enables consistent performance across production batches.

GEARKO applies precision manufacturing processes and selective assembly techniques to maintain tight backlash control while supporting scalable, cost-effective production.

3. Thermal Expansion Compensation

During operation, internal components experience temperature changes that cause expansion of gears, shafts, and housings. Insufficient backlash can disappear entirely under thermal growth, leading to noise, accelerated wear, or gear seizure.

GEARKO gear reducers are designed with backlash values that remain stable across the full operating temperature range, ensuring reliable performance in continuous-duty and high-load environments.

4. Lubrication and Wear Protection

Backlash plays a vital role in maintaining an effective lubrication film between meshing gear teeth. Proper clearance allows lubricant circulation and heat dissipation, reducing surface fatigue such as pitting or scuffing.

GEARKO’s gear reducer designs optimize backlash in conjunction with lubrication strategy, helping achieve long maintenance intervals and reduced operating costs.

5. Noise and Vibration Control

Backlash has a direct impact on noise, vibration, and harshness (NVH). Excessive backlash can cause gear rattle, while insufficient backlash increases meshing noise and vibration.

Through advanced inspection and quality control, GEARKO ensures backlash consistency to deliver quiet, smooth-running gear reducers suitable for automation, robotics, and industrial machinery.

Application-Specific Backlash Optimization at GEARKO

Different applications require different backlash characteristics, and GEARKO tailors its gear reducers accordingly:

- Precision automation and robotics: Low, controlled backlash for accurate positioning

- Industrial power transmission: Balanced backlash for durability and shock resistance

- High-speed applications: Optimized backlash for thermal stability and dynamic performance

- Heavy-duty machinery: Increased tolerance to accommodate deformation under high torque

This application-focused approach ensures that each GEARKO gear reducer meets real-world performance demands rather than relying on a one-size-fits-all solution.

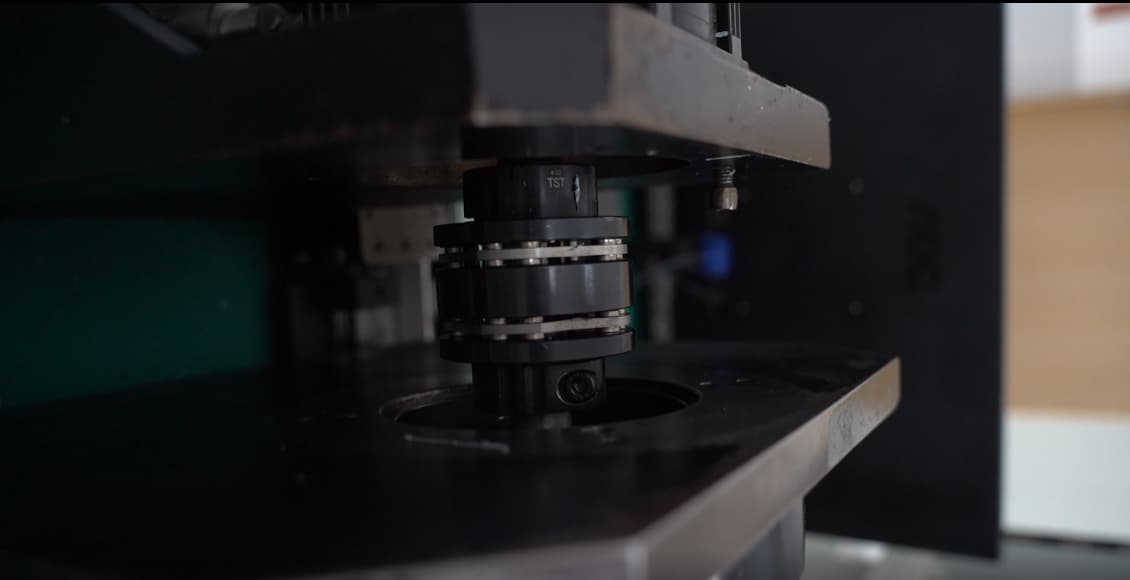

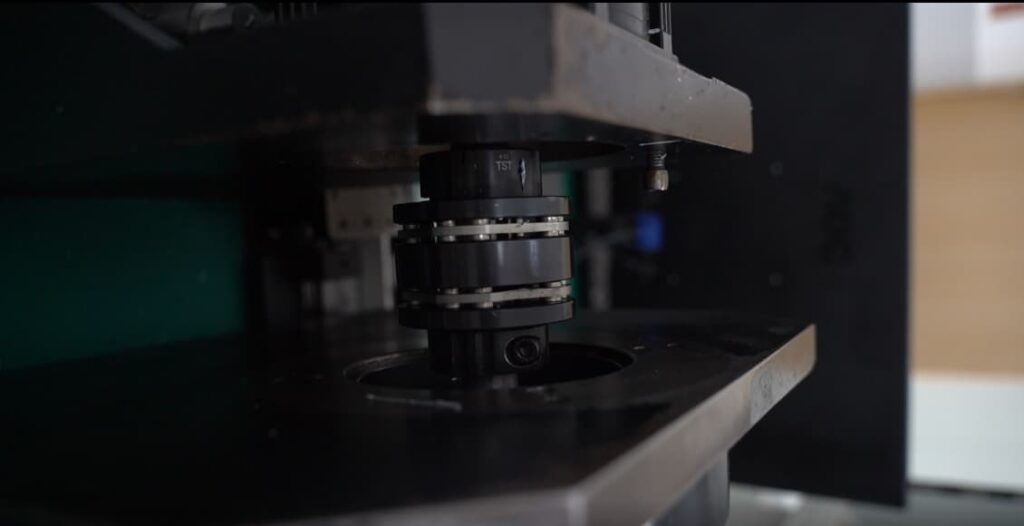

Backlash Control in GEARKO’s Manufacturing Process

To achieve consistent and reliable backlash control, GEARKO employs:

- Precision gear cutting, grinding, and finishing

- Matched gear pairing and selective assembly

- Adjustable bearing preload and shim systems

- Advanced measurement and inspection equipment

- Design validation through simulation and tolerance analysis

These practices allow GEARKO to deliver gear reducers that combine precision, durability, and repeatable quality.

Conclusion

Backlash is not a flaw to be eliminated, but a vital engineering parameter that defines the performance and reliability of a gear reducer. For a quality manufacturer like GEARKO, mastering backlash control is central to delivering products that meet demanding industrial requirements.

By integrating backlash optimization into design, production, and quality assurance, GEARKO provides gear reducers that achieve the ideal balance of precision, durability, low noise, and cost-effectiveness—supporting long-term performance across a wide range of applications.