- 12月 23, 2020

- News

- 0 Comments

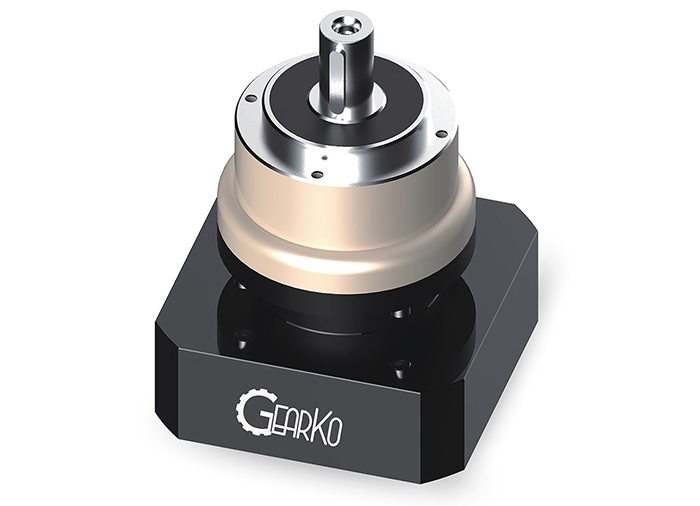

Many friends do not know much about planetary gearbox oil immersion, today to give you an analysis of the planetary gearbox oil immersion problem. The smooth surface of the planetary gearbox is suitable for sites where the circular speed of the drive shaft seeping into the oil is less than 12m/s and the circumferonal speed of the vortex rod is less than 10m/s.

In order to ensure that the drive gear tooth joint is smooth enough, and to avoid excessive oil stirring, the transmission components inside the planetary gearbox should not penetrate into the deep part of the shell oil tank, should not be deeper than shallow. For each output power of 1kw, the residual oil required for a single-stage planetary reducer is about 350 to 700 cubic meters, and the proportion of residual oil required for each output power of a multistate planetary reducer is the equivalent series.

In the transmission mechanism of a multistration planetary gearbox, the oil immersion depth of the high speed gear should be less than 10mm, about 0.7 teeth deep. The oil immersion depth at low speed is about (1/6 to 1/3) the transmission gear is half-way through, or the main deceleration chassis cover, part of the surface of the case seat is made into a slope, so that the oil immersion depth at high speed is the same as the oil immersion depth at low speed.

For planetary gearboxes, when the vortex rod under the transmission system, the oil surface aspect ratio should be less than the diameter of the vortex rod’s teeth circle, the smallest steel bead control center of the roller bearing on the vortex shaft can not be crossed to prevent damage to the lift output power. If the diameter of the vortex rod is less than the diffusion diameter of the rolling bearing flip body management center, if the vortex rod is allowed to seep into the oil, in order to avoid this situation, there are two ways to make the rolling bearing immersion oil deeper than the flip body management center:

Select the method for the splash cargo ship. Sprinkle the finished oil onto the booster with a splash of cargo ship on the vortex shaft to ensure a smooth tooth joint.

Set up a sputtering oil pan with reinforced ribs on the vortex shaft and splash the oil onto the vortex shaft and the booster end with the sputtering oil pan to make it finish smooth.

Finally, it is important to remind everyone that the planetary deceleration tank oil-soaked finish is the transmission gear, vortex rod or booster rod and other transmission parts into the tank, through the rotation of the transmission, the tank of the finished oil to the tooth joint, and then throw it out of the inner wall, and then heat pipe cooling.