- 9月 14, 2020

- News

- 0 Comments

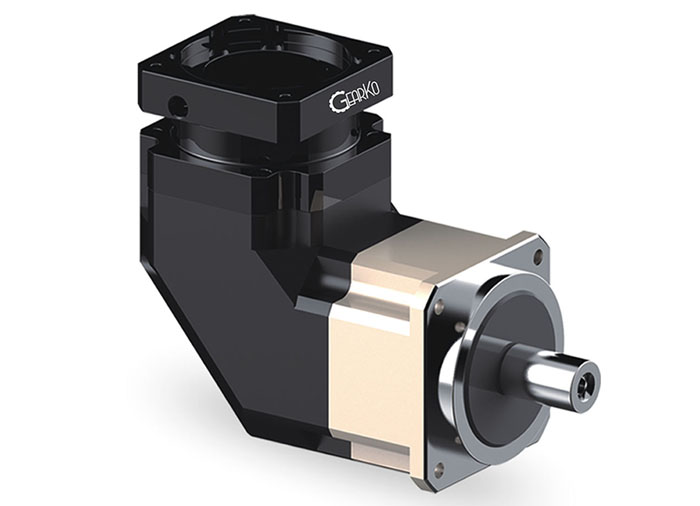

In the gearbox family, the planetary gearbox is widely used in servo, step, DC and other transmission systems because of its small size, high transmission efficiency, wide deceleration range and high precision. Its function is to reduce the speed increase torque and reduce the inertia ratio of the load/motor under the premise of ensuring precision transmission. Proper installation, use and maintenance of the gearbox is an important part of ensuring the normal operation of machinery and equipment. Therefore, when installing planetary reducers, it is important to carefully assemble and use them in strict accordance with the following installation and use.

The first step.

Before installation to confirm that the motor and the gearbox are intact, and strictly check that the motor and the gearbox connected to the dimensions of the various parts match, here is the motor positioning boss, input shaft and gearbox grooves and other dimensions and matching tolerances.

Step two.

Spin the screws on the dust hole on the outside of the deceleration delan, adjust the PCS system clamping ring so that its side holes are aligned with the dust holes, and insert the inner hexagon tightness. After that, remove the motor shaft key.

Step three.

Connect the motor to the gearbox naturally. When connecting, it is important to ensure that the gearbox output shaft is the same as the motor input shaft and that the outer flan is parallel. As if the heart degree is not consistent, it can cause the motor shaft to break or the gear of the gear of the reducer to wear out.

In addition, during installation, it is strictly forbidden to hit with a hammer, etc., to prevent axial or radial forces too large damage to bearings or gears. Be sure to tighten the mounting bolts before swirling them tightly. Before installation, wipe the rust-proof oil of the motor input shaft, positioning boss and gearbox connection with gasoline or zinc sodium water. The aim is to ensure the tightness of the connection and the flexibility of operation, and to prevent unnecessary wear and tear.

Before connecting the motor to the gearbox, the motor shaft keyway should be perpendicular to the tight bolt. In order to ensure uniform force, the mounting bolts in any verse position are first screwed, but do not tighten, and then the mounting bolts in the other two verse positions are finally tightened one by one four mounting bolts. Finally, spin the tight force bolt. All tight bolts need to be secured and checked by the torque plate hand according to the indicated fixed torque data.

The correct installation between the gearbox and the mechanical equipment is the same as the correct installation between the gearbox and the drive motor. The key is to ensure that the gearbox output shaft is in the same heart as the drived part of the shaft.