- 10月 13, 2020

- News

- 0 Comments

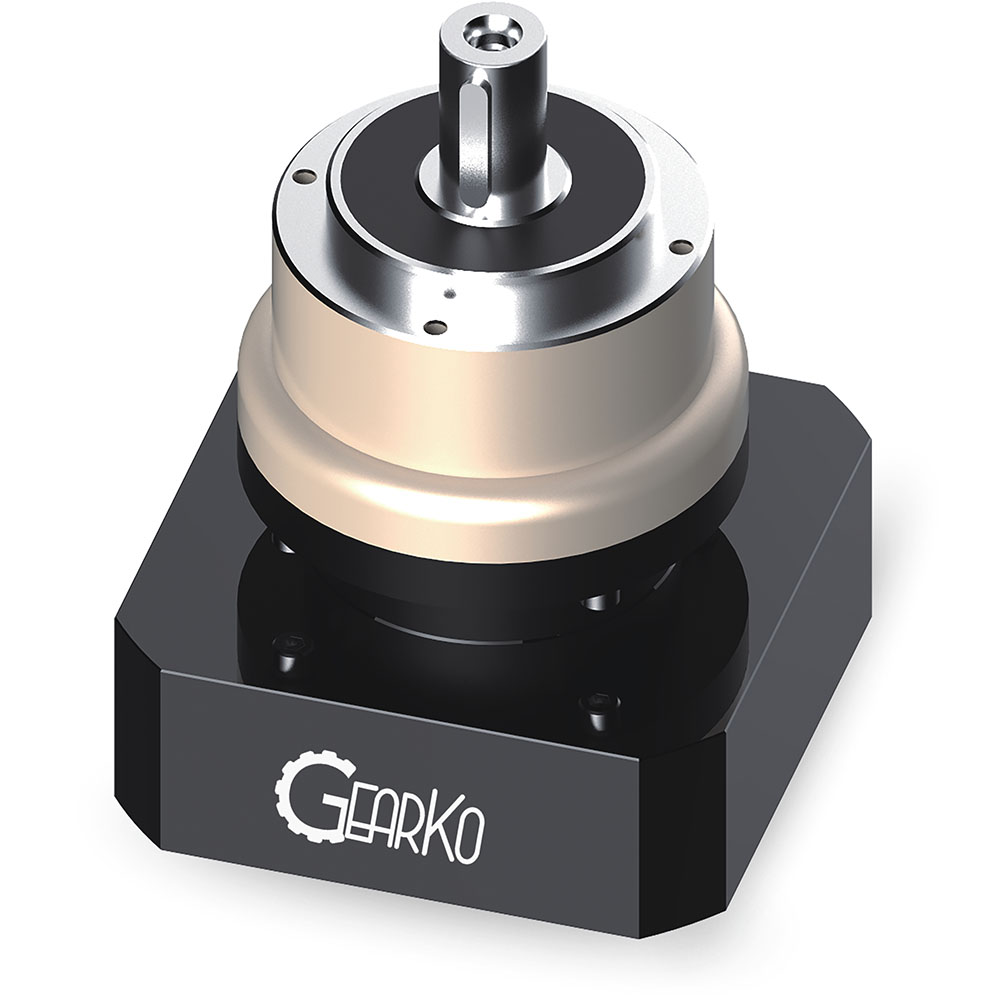

Gear reducer is generally used for low-speed high torque transmission equipment, the motor, internal combustion engine or other high-speed running power through the gear on the input shaft of the gear reducer with a small number of teeth to engage the large gear on the output shaft to achieve deceleration purposes, but in the course of operation there will be transmission is not smooth, then the gear reducer transmission is not smooth what is the reason? The GearKo gear reducer manufacturer below has found the reason for you.

Gear reducer normal state of things the maximum temperature should not be higher than 45 degrees Celsius, such as the emergence of high temperature should immediately stop the rigid inspection, the same usually appear this problem target is the original reason for the selection of this tonnage of gear reducer small overload signs, or the worm and the end cover of the worm wheel together pressed into the high temperature environment of too tight, input speed is not cleared In the outer worm gear reducer for butter lubrication, the maximum speed of the worm shaft must not be higher than 1000min/s, such as the input speed is too high and card death and other environments, high temperature disposal penalty is low input speed, check whether the embedding of the pressure cap is too tight and whether the planetary gear reducer oil shortage signs.

The reason for the tremors that occur after the additional load in the utilization process is the uneven pitch of the screw, the uneven parting of the gear reducer worm, the plane pressure bearing and the taper bearing quality is not up to standard, the upper and lower sheaths of the screw are all too tight.