- 12月 2, 2020

- News

- 0 Comments

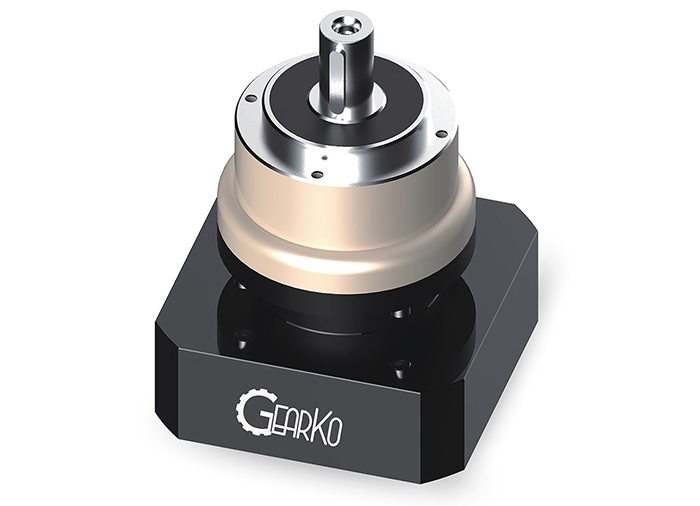

How do the gearbox do the lubrication work on the planetary gearbox? Planetary gearboxes, like other reducers, need to be lubricated below, which not only speeds up the operation of the planetary gearbox, but also protects the proper operation of the gearbox. How to do a good job of lubrication of planetary gearboxes? Take a closer look at the details of the gearbox below.

When selecting greases according to the bearing load of the walking planet reducer, a grease with a low needle entry should be selected for heavy loads. In addition to the small needle in the high-pressure work, but also have a higher oil film strength and extreme pressure. When choosing grease according to environmental premise, calcium-based grease is not easily soluble in water and is suitable for dry and less moisture environment. When choosing grease according to operating temperature, the main index should be drop point, oxidation stability and low temperature performance, drop point can generally be used to evaluate high temperature performance, bearing actual operating temperature should be lower than drop point 10-20 degrees C. Synthetic greases should be used at a temperature below 20-30 degrees Celsius.

Planetary gearbox lubrication, but also caused by poor lubrication of one aspect, splash-type lubrication, mainly used in high-speed situations, for this medium-load, low-speed situation is obviously not suitable. Long life, low maintenance of closed full-life gearbox, boiler discharge into gearbox, tooth chain stepless transmission, planetary gearbox lubrication, can also be used for centralized grease supply equipment lubrication.

The unreasonable lubrication method and structural design defects of the planetary gearbox result in the unreliability of the application of this planetary gearbox. Reflected problems, first of all, the service life is reduced, followed by loud noise and vibration, resulting in frequent maintenance. And with each overhaul, eccentric bearings and needle sleeves must be replaced to increase the cost of repair. Bearing work is not very stable, due to the role of gravity and mechanical movement of vibration, will inevitably cause the bearing in the axial position to produce a small displacement, this relative motion is very harmful, constant impact may lead to the deformation and break of elastic bezel, bearings from the shaft off the danger, even if the bearing does not fall off, will also produce a lot of noise due to vibration.