- 1月 24, 2021

- News

- 0 Comments

What are the precautions when connecting a servo motor? Here’s a little editor to explain it to you.

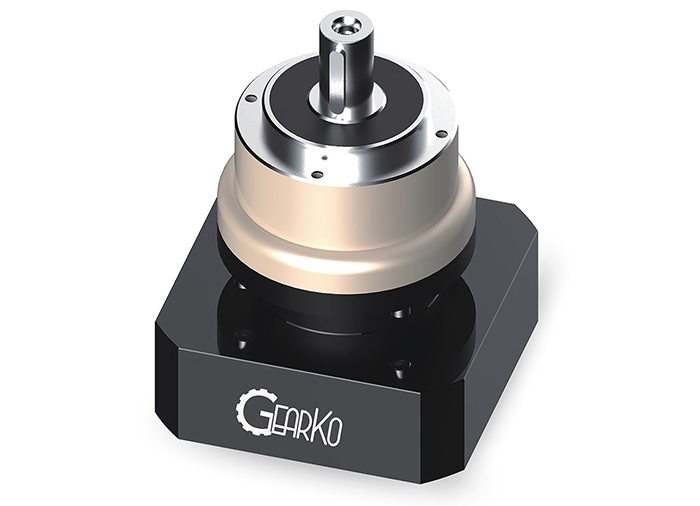

First, the planetary gearbox in the installation process, we should pay special attention to the transmission center axis of the pair, the error in the pair can not exceed the amount of compensation planetary gearbox coupling in use. After the medium gearbox is adjusted as required, it can get better transmission results and a longer service life.

2. When the planetary gearbox is connected with the servo motor, when the transmission is installed on the output shaft of the reducer, attention should be paid to the soft operation, prohibit the rough installation with tools such as hammers, preferably with the internal thread of the assembly fixture and the end shaft, and press the drive into the reducer with the force of bolt tightening, so as to prevent damage to its internal components.

Third, the planetary reducer uses many kinds of couplings, but it is best not to use steel fixed couplings, this coupling is difficult to install, once installed improperly, it will increase the load, easy to cause bearing damage, and even lead to output shaft breakage.

Fourth, the fixation of the planetary reducer is very important, to ensure stability and firmness, in general, we should install the deceleration stepper motor on the horizontal base or base, at the same time should exclude the oil in the drain tank, so that the cooling air circulation smoothly. Planetary reducers are poorly installed, the base is unreliable, starting, vibration, etc. can occur, and unnecessary damage to bearings and gears can occur.

5. The planetary gearbox and servo motor connection of the transmission joint, if necessary, should be attached to the protective device, such as the joint has a bulge or the use of gears, shropper transmission, etc. , if the output bearings are subject to a larger radial load, should also be selected to strengthen the type.

6. The installation position of the decelerator shall ensure the operation of the staff, including easy access to cursors, air plugs and exhaust plugs. After the planetary decelerator is installed, the inspectors should thoroughly check the installation location in sequence to determine whether the fasteners are reliable, etc.

Seven, the gearbox before running, but also to do a good job of running preparation, remove the oil tank breather plug replaced with a breath plug, open the oil plug screw to check the height of the oil line, add lubricants beyond the oil plug screw to the hole overflow, and then tighten the oil plug and confirm that there is no error, you can start the test run.

Eight, deceleration step motor test run time must not be less than two hours, in line with normal standards, smooth operation, no vibration, no noise, no leakage, no impact, if there are anomalies should be eliminated in a timely manner.