- 8月 31, 2020

- News

- 0 Comments

The twin support of the planetary reducer and the single support of the planetary reducer refer to the support of the gears, i.e. the planetary frame of the planetary reducer. The planetary frame of the planetary reducer and the output axis of the planetary reducer are one-size-of-one structures, so the planetary frame of the planetary reducer does not do well directly affects all aspects of the performance of the planetary reducer. Let’s first look at the difference between single and double support.

1. Structural differences.

Single support on the planetary shelf hit three pin holes, put three pins, and then the gear fixed on the pin, one side of the gear is the planetary frame, the other side is suspended, the back put a bezel to separate.

The double-supported planetary frame passes through the CNC, and then hits the pin hole in the upper machining center, and must also ensure that the pin holes on the upper and lower sides are completely concentric (otherwise the gears and gears do not engage), and then put in the gears, and finally fixed with pins, both sides of the gears are supported by the planetary frame.

2. The difference between forces.

A single support structure is one side of the gear on the planetary shelf that is forced on only one side.

The dual support structure is the force on both sides of the gear on the planetary frame,

3. Differences in performance.

The single-support gear will be driven in the opposite direction of the output shaft, the planetary gear will increase the coefficient of friction with the ring gear within the planet, resulting in increased noise, reduced efficiency, higher temperature, and even serious oil leakage.

In addition, the planetary reducer is mainly used to cooperate with the use of servo motor, and servo motor is characterized by small size, high precision, frequent positive reverse use, when the single-support planetary reducer with servo motor frequent positive reverse use, single-support planetary gearbox on the planetary frame is easy to produce rigid deformation, so will lead to a single-support planetary gearbox gap becomes larger.

The dual support structure of the planetary reducer will not be, because both sides of the gear are supported by the planetary frame, so the gear will not be side-by-side when the gearbox is driven, and the gear pins will not produce rigid deformation. 、

4. The difference in cost.

The twin support structure of the planetary reducer first uses CNC in the middle of the planetary frame, and then punches holes in the upper processing center, and must also ensure that the pin holes of the upper and lower two faces are completely concentric, and if the pin holes of the two faces appear to be biased, that is, the entire planetary frame is scrapped. Therefore, the dual support structure of the planetary reducer is about 20 percent more than the cost of processing the single support structure of the planetary gearbox.

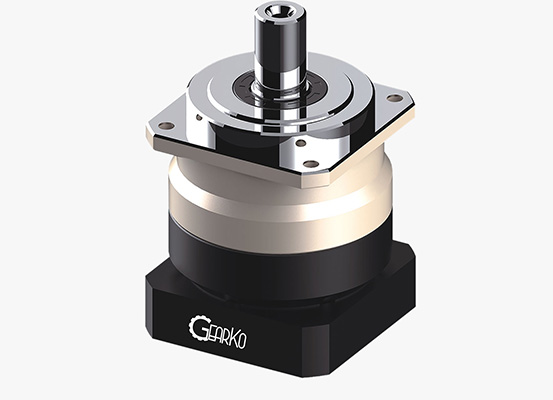

Planetary gearbox.

The twin support of the planetary reducer and the single support of the planetary reducer refer to the support of the gears, i.e. the planetary frame of the planetary reducer. The planetary frame of the planetary reducer and the output axis of the planetary reducer are one-size-of-one structures, so the planetary frame of the planetary reducer does not do well directly affects all aspects of the performance of the planetary reducer.

The internal structure of the planetary gearbox includes planetary frames, planetary gears, solar wheels, inner ring gears, and other parts.

The planetary reducer is dually supported, and both sides of the gear are supported by the planetary frame:

At present, the planetary gearbox has two series of straight and oblique teeth, of which the oblique teeth are using dual support structure to ensure high accuracy requirements.

The dual-supporting structure of the planetary gearbox unified use of dual-support independent planetary support, not only to ensure stability, but also to ensure high accuracy, to ensure stable and reliable quality. Independent one-piece planetary bracket, dual support structure, full cast two-stage combination, coaxial square flange output, low back gap, positioning accuracy, good steel, carrying capacity, low noise, long life, small size, beautiful appearance, easy installation and so on, the connection between the input end and the motor using barrel clamping mechanism and dynamic balance analysis, to ensure that the combination of high input speed interface concentric power transmission.